Cyclic Polarization

Cyclic polarization measurements are typically used to characterize metals and alloys that derive their corrosion resistance from the formation of a thin passive film.

Alloys such as 316LVM and MP35N, often used in implantable medical devices, derive their corrosion resistance from passivity. These alloys can be susceptible to localized corrosion due to breakdown of their passive films.

Cyclic polarization measurements done in accordance with ASTM F2129* are used at EIC Biomedical to assess corrosion resistance of these and related alloys. Cyclic polarization measurements are also useful for characterizing noble metal electrodes such as platinum and gold, and in particular for assessing the likely severity of galvanic corrosion between noble and non-noble metals in implantable devices.

Examples of Cyclic Polarization Curves

These measurements are usually made in Ringerís solution at 37degC using a 5%CO2/95%N2 gas sparge to control pH. A gas sparge of 5%CO2/6%O2/89%N2 is used when investigating the influence of dissolved oxygen gas.

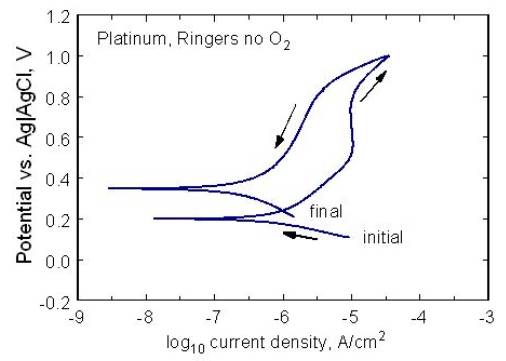

Platinum |

|

|

Potentiodynamic cyclic polarization of a platinum electrode in Ringers solution at pH 7.4 and 37oC. The Ringers was purged with 5%CO2/95%N2 to maintain pH and remove dissolve oxygen gas. |

|

|

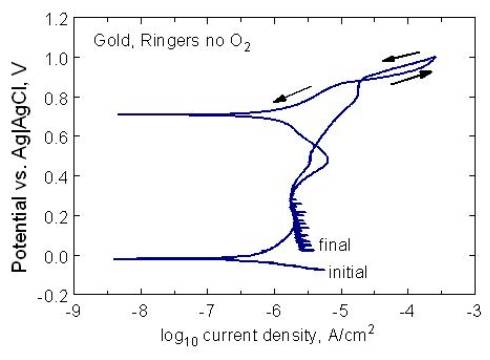

Gold |

|

|

Potentiodynamic cyclic polarization of a gold electrode in Ringers solution at pH 7.4 and 37oC. The Ringers was purged with 5%CO2/95%N2 to maintain pH and remove dissolve oxygen gas. |

Features include:

• Suitable for SIROF and other low impedance electrode coatings

• Array dimensions up to 90 mm with a wide range of electrode number and size available

• Exceptional in vitro and in vivo stability

• Laboratory and chronic animal connectors available

• Arrays are available on polyimide, Parylene, LCP, glass and silicon

Contact us to discuss Cyclic Polarization at EIC Biomedical.

Limitations: The use of test results and test articles for any application is the sole responsibility of the end-user. Results of in vitro testing do not establish in vivo safety. The performance of electrodes and electrode devices and the robustness of encapsulation may depend on the manner of use, post-fabrication history, and other factors that are not predictable.